5.1.2021

Natural flax fibres are a class of green engineering reinforcements with excellent damping and stiffness to weight ratio. Natural fibres such as flax have already found their way to many applications such as bio-composite bridges, sports applications, and racing cars.

My PhD goal in FibreNet project is to increase the competence of biocomposites (e.g. mechanical performance) by tuning the fibre/matrix adhesion. In specific loading conditions such as fatigue, it is essential to have a substantial fibre/matrix bonding (or off-axis strength of composites). However, good fibre/matrix adhesion might not be the exact solution to achieve a better impact resilient composite. Engineers should delicately optimise the fibre/matrix adhesion to design a biocomposite which offers good fatigue and impact strength at the same time. Before developing a fibre surface treatment method for a specific engineering need, it is essential to understand the state of fibre/matrix bonding in various loading conditions and scales.

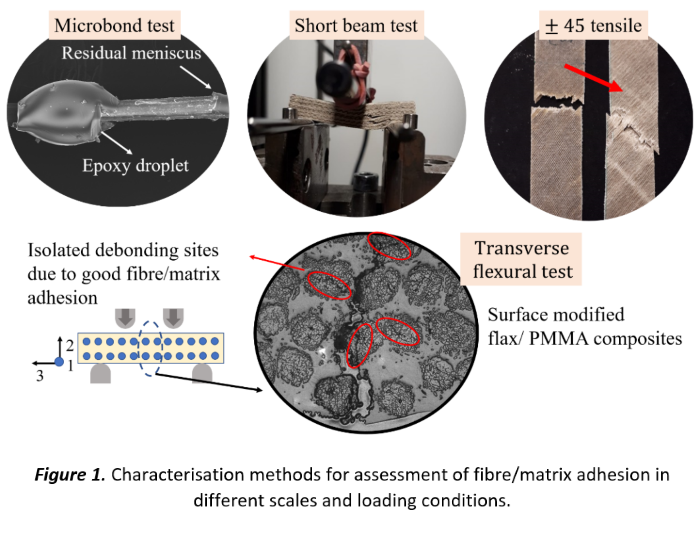

Figure 1 above presents several characterisation methods which I actively use in the process of developing a fibre surface modification method:

- Microbond test measures the interfacial shear strength (IFSS) between single flax fibre and a picoliter sized resin. It is a very efficient method for the research and development stage as a limited amount of materials are needed. The results can be used for both qualitative and quantitative evaluation. New microbond technologies such as FIBrobotics© offer high throughput data, with precision and repeatability.

- Short beam test is a method for the assessment of interlaminar shear strength ILSS (shear strength between plies in composites). ILSS is an important material property in cases where delamination is critical, e.g. impact. ILSS test is usually applicable only for composites with brittle matrix systems, e.g. epoxies.

- Tensile test of composites with ±45 layup is like the microbond test (failure due to shear loading) but in macroscale. It gives a good approximation of in-plane shear strength (IPSS) of composites. Of course, in ±45 test, the failure might be due to the combination of both fibre/matrix debonding and delamination. IPSS values tend to be higher than IFSS as in the former the result reflects the contribution from fibre/matrix interface and fibres. Also, artefacts present in composites can affect the IPSS values, but finally, IPSS can be considered as a macroscale (or in-service) interfacial shear strength.

- Tensile or flexural test of composites with 90 ̊ layup gives a good estimation on off-axis strength of composites which is relevant to fatigue performance of structures in service. The ultimate strength and strain of transverse flexural (or tensile) test is dominated by the extend of fibre/matrix bonding and those values of the matrix itself. In these types of tests, there is a significant strain concentration in the matrix, and fibre/matrix interfaces which created microcrack and the coalescence of microcrack leads to the final failure of the composites. As in Figure 1, good fibre/matrix bonding creates isolated debonding sites and deflects the crack path. On the contrary, in the case of weak interfacial adhesion, the crack usually follows a relatively straight line.

Finally, based on the combination of these characterisation results, we can design a surface treatment solution. Figure 2 is related to one of my recent studies in which I try to preserve the good fibre/matrix adhesion and in-plane properties of flax fibre/epoxy composites and enhance the damage tolerance in the same time with fully biobased and hydrophobic coatings.

The detailed outcome of this research will be available as open-access journal articles on the FibreNet website.

Relevant blog posts by FibreNet:

- Enabling bio-composite in everyday life

- Microrobotics and how to use it in fibre studies

- Does shape matter?

- Sustainability matters!

- Molecular dynamics, Molecular dynamics! wherefore art thou Molecular Dynamics?

- Life Cycle Assessment: Benefits and limitations

- Lightweighting of paper board – adding sustainability to food packaging

Writer:

Farzin Javanshour

ESR1- Tampere University